What Are Plastic Bearings?

Plastic bearings (also called resin bearings) are bearings whose main components are made of plastic. While most conventional bearings are metal, plastic bearings are chosen for environments where metal bearings cannot be used or are less efficient.

A standard deep‑groove ball bearing consists of an outer ring, inner ring, cage, and balls.

In plastic bearings, the outer ring and cage—or the outer ring, cage, and inner ring—are often molded from resin. However, the inner ring, balls, or cage (retainer) may also be made of materials such as metal, glass, or ceramics, depending on performance requirements.

Photo courtesy of Kashima Bearings. |

Plastic bearings (plastic bearings / resin bearings) offer several advantages that metal bearings do not: ・Lightweight ・Low noise ・No performance loss when exposed to liquids ・Will not rust (highly corrosion‑resistant) |

Depending on the application, plastic bearings come in many variants:

・All components made of plastic

・Only the balls made of stainless steel, glass, etc.

・Outer ring, cage, and inner ring made of plastic

・Only the outer ring made of plastic

・Only certain parts made of plastic

Main Features of Plastic Bearings (vs. Metal Bearings)

Typical Characteristics & Benefits

Unique plastic properties include electrical insulation (non‑conductive), non‑magnetic behavior, light weight, low noise, rust‑free (water‑resistant), and corrosion‑free (chemical‑resistant).

・Lightweight

・Low noise

・Rust‑free or highly rust‑resistant in water, seawater, or steam (water resistance)

・Corrosion‑free or highly corrosion‑resistant to chemicals (chemical resistance)

・Complex shapes can be produced

・Electrically insulating

When Both Rings Are Plastic

Metal bearings normally require grease to prevent seizure during rotation. When both the outer and inner rings are plastic, the bearing can run without grease, eliminating grease leakage and dust or powder adhesion. This makes them ideal in food‑processing lines, or in dry, high‑temperature environments where grease would harden.

・Maintenance‑free—operates without oil/grease

・Grease will not wash out even in underwater or liquid applications

Drawbacks of Plastic Bearings

Compared with metal bearings, plastic bearings inevitably have lower load capacity. In addition, plastic expands and contracts more with temperature and humidity, so they are not suitable where high dimensional accuracy is required.

・Lower load capacity than metal

・Limited precision

Typical Applications of Plastic Bearings

|

Perhaps the place you encounter them most often is in the roller slides of office desk drawers—taking advantage of their light weight, corrosion resistance, and—above all—quiet operation. Plastic bearings are used in many other applications as well. |

Main Applications

・Office equipment & furniture

・Residential hardware

・Cleaning systems (semiconductors, film, etc.)

・Plating equipment (semiconductors, general industrial machinery)

・Transport lines in dyeing / textile machinery

・Roller conveyors (food industry, fisheries, etc.)

・Static‑discharge parts in control equipment

・Dryers

・Fountains & environmental devices

・Various other industrial machines

List of Plastic Bearing Manufacturers

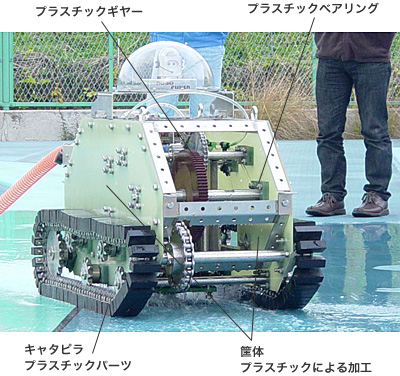

Kashima Bearings.

A specialist in plastic bearings. Also produces plastic gears, plastic pillow blocks, and other machined plastic products. [Osaka, Nishiyodogawa‑ku]

TOK, Inc.

A pioneer in plastic bearings. Supplies drawer guides for refrigerators and shop fixtures, guide rollers for crane‑game machines, shutter guide rollers, and more. [Tokyo, Itabashi‑ku]

Matex & Co., Ltd.

Manufactures plastic, stainless‑steel, water‑resistant, and chemical‑resistant bearings. [Osaka, Naniwa‑ku]

Takai Seiki Co., Ltd.

A specialist in bearing cages. Also manufactures and sells plastic plain bearings and plastic bearings. [Fujisawa, Kanagawa]

Eastern Seiko Co., Ltd.

Produces plastic bearings for casters, conveyors, and other applications. [Tokyo, Chiyoda‑ku]

BNL Bearings

Standardizes and sells plastic bearings from UK‑based BNL Bearings for Japan and the wider Asian market. Holds a top share of the global bearing market. Formerly “Sarnatec Japan Co., Ltd.” [Tokyo, Chuo‑ku]

Oiles Corporation

Manufactures and sells self‑lubricating bearing materials (oilless bearings), focusing on plain bearings. [Tokyo, Minato‑ku]

Konishisangyo Co., Ltd.

Specializes in plastic bearings that combine a polyacetal (Delrin) outer ring with steel balls and inner race—known for durability and cost performance. [Tokyo, Minato‑ku]

Related PagesPlastic Deep Groove Ball Bearings |