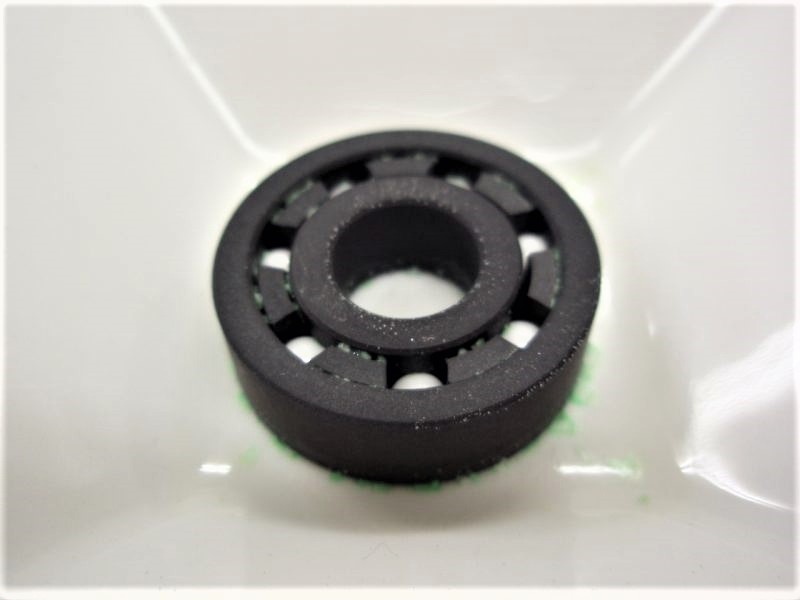

Deep groove bearings (single row deep groove ball bearings) are the most representative shape of ball bearings (rolling bearings) and are the most widely used type of bearings. They consist of a combination of raceways (inner and outer rings), balls, and cages that support the balls.

They primarily handle radial loads (loads perpendicular to the shaft) but can also support axial loads in both directions.

They are suitable for applications requiring low friction and stable rotation.

The grooves of the raceways are slightly larger arcs than the radius of the balls, and the balls make point contact with the raceways. Compared to plain bearings, using balls reduces rotational resistance, making them suitable for applications requiring stable rotation.

Bearing Structure

Our company mainly uses plastic for bearing materials. Plastic bearings have various features that differentiate them from metal bearings, such as being “usable without lubrication or oil” and “not rusting or corroding in water or chemicals.”

Comparison of Metal Ball Bearings and Plastic Ball Bearings After Immersion in Chemical Solutions for 24 Hours

| Metal Bearings | ||

| Saltwater | Acidic Cleanser | Alkaline Cleanser |

|

|

|

| Plastic Bearing | ||

| Saltwater | Acidic Cleanser | Alkaline Cleanser |

|

|

|

Characteristics of Resin Bearings

Plastic bearings are used in special environments where metal bearings cannot be used. However, no single type of resin is suitable for all special environments, so we recommend materials based on the specific environment in which they will be used. Since we manufacture them through machining, we can create any shape.

If you have any issues with bearings, feel free to contact us. We are happy to visit and provide support.

Related Pages for This Article

Drawings