Plastic bearings generally refer to bearings made from resin.

Among them, plastic bearings can be mainly classified into three types.

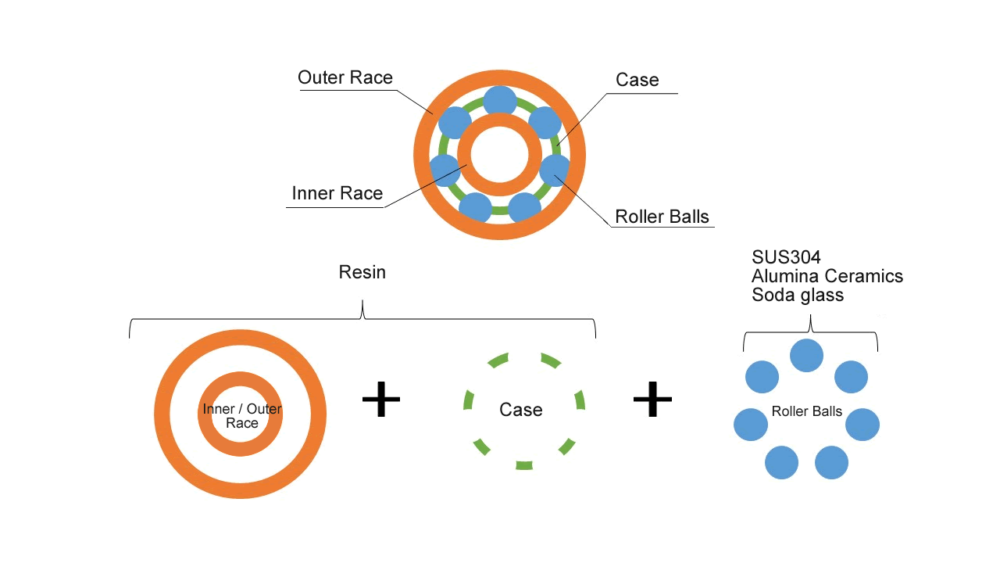

When you hear the term “bearing,” the first thing that comes to mind is probably ball bearings, which consist of three main components: raceways, cages, and balls.

Furthermore, the raceway can be divided into an outer ring and an inner ring as shown in the diagram below.

Raceways & Cages: Resin Type

The first type of plastic bearing introduced is one where the raceways and cages are made of resin, like our products.

This type does not require any grease or oil as the resin is self-lubricating.

Additionally, since both the raceways and cages are made entirely of resin, they can be used underwater, in seawater, or in chemical solutions without rusting or corroding.

They are also suitable for non-magnetic and insulating applications, and are effective in situations where weight reduction is needed.

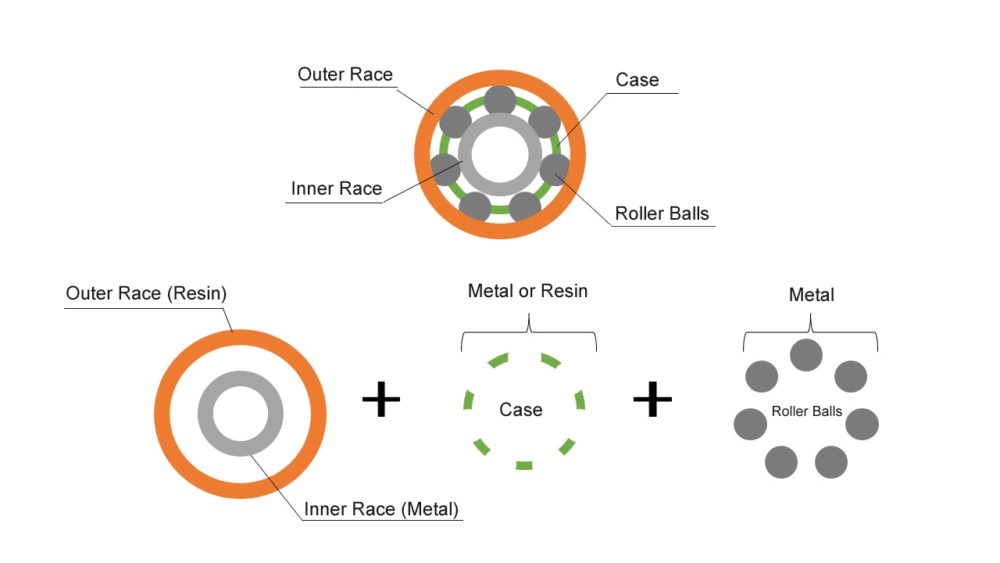

Outer Ring: Resin, Cage: Metal or Resin Type

The next type introduced is one where the outer ring is made of resin.

Compared to metal bearings, this type is less likely to damage the mating material even when used in guiding applications, and it excels in noise reduction. Additionally, the shape and material of the outer ring can be customized according to the application.

Applications include sliding doors, shutters, and cabinet drawers, where smooth opening and closing is desired. Due to its ability to prevent damage to the mating material, it is also used for guide rollers and transport rollers.

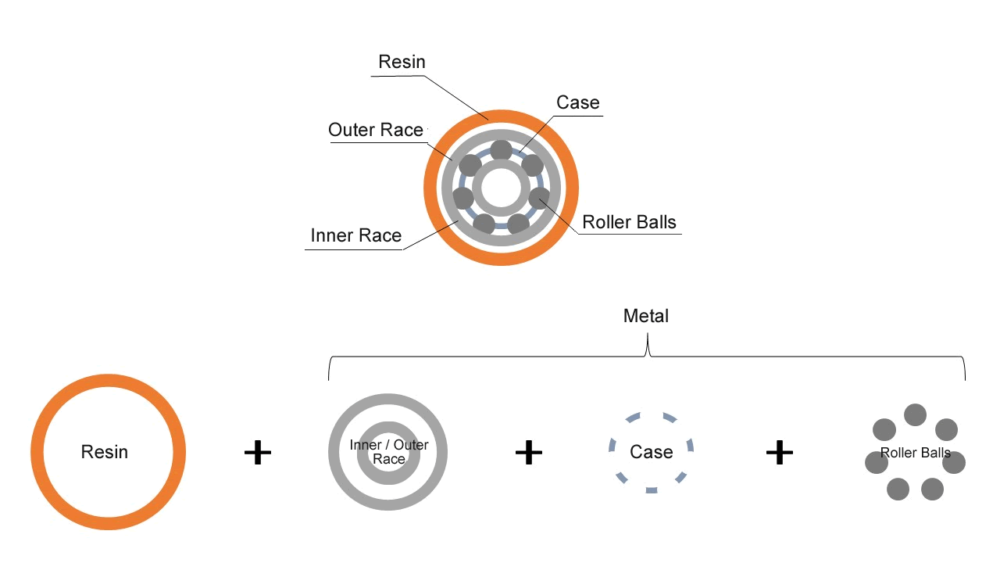

Outer Ring & Cage are Metal, with Resin Coating on the Outer Ring

The third type is a resin-coated bearing, where resin is wrapped around the outer diameter of a metal bearing.

Unlike the previously mentioned bearings with resin outer rings, this type has a fully metal bearing core wrapped in resin.

It is also referred to as a “resin-coated bearing” or “resin-wrapped bearing.” This type is often used in applications where durability is required.

Since it uses resin on the outer diameter, it is less likely to damage the mating material, and the shape and material of the resin portion can be selected according to the application.

Applications are similar to those of the previously mentioned resin outer ring bearings and include guide rollers and transport rollers in parking lots and bicycle parking areas, as well as rollers that control the posture of escalator steps, where relatively high loads are applied.

Summary

There are mainly three types of “Plastic bearings,” each with its own advantages and suitable applications.

The plastic bearings introduced so far are deep groove ball bearings, but our company offers various shapes such as self-aligning, angular contact, and thrust ball bearings.

In addition to ball bearings, we manufacture almost all types of “bearings” from resin, including resin plain bearings, resin slide bearings, and pillow block bearings, with a wide variety of materials and shapes, making us one of the top companies in the industry in terms of selection.