Magnesium alloy screws and bolts

Ultra-lightweight! The world’s first successful mass production

Ultra-lightweight! The world’s first successful mass production

Magnesium has a specific gravity that is 2/3 that of aluminum and 1/4 that of stainless steel, making it the lightest metal used as a structural material. It has excellent specific strength, electromagnetic shielding, and vibration absorption properties, and does not cause electrolytic corrosion when in contact with magnesium alloys, making it suitable for fastening magnesium alloy housings, etc., and is used in a wide range of applications in the fields of information, home appliances, automobiles, and aircraft. A new history of magnesium alloys begins here.

Features

- Lightweight (lightest among structural metals, specific gravity 1.78)

- Good vibration absorption

- Excellent electromagnetic shielding

- Heat dissipation

- Good dent resistance

- Recyclability

- High specific strength

Mechanical properties

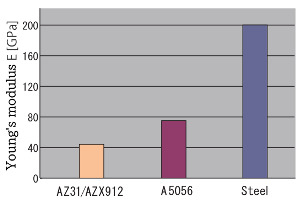

Elastic constants of magnesium

|

Mg exhibits a very low Young’s modulus compared to other metal alloys. The male bolt with the same Young’s modulus as the fastened part is ideal to correctly engage the female thread. Mg alloy bolts protect the female thread fabricated in precious Mg parts against fractures due to the uneven loading. |

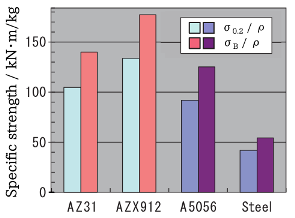

Specific strength

|

Specific strength represents material’s strength divided by its density. This value is nearly equivalent to the bolt tensile strength divided by its density. As the specific strength of AZ912 bolt is three times greater than that of soft steel bolts, AZX912 bolts contribute to the reduction of weight by 66 %. For example, total weight of AZX912 bolts becomes one third of that of soft steel bolts to bear an external load by fasteners. |

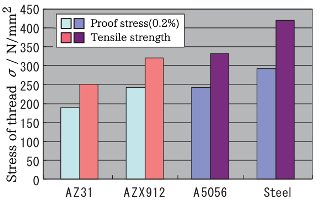

Tensile strength of bolt and its proof stress

|

AZX912 bolts exhibit the equivalent strength of A5056 Al alloy bolts. Presently, we are developing new Mg alloy bolts with much higher strength than A5056. We will continue the development for new reliable items to respond to the expectation of customers. |

Company Profile

Company Profile